How to increase your coating material yield in sputtering

- Christos Pernagidis

- 3. Apr. 2021

- 2 Min. Lesezeit

Aktualisiert: 27. Juli 2021

Investigation of Titanium target pieces for PVD sputtering

After using Titanium Grade 2 we faced different erosion profiles and obvious the material seems to have also different grain size

Preparation: US cleaning in 2-Propanol, Cross section through the sputter groove

Method: Scanning Electron Microscope LEO 1530 VP| Light Optical Microscope Olympus BX51, digital imaging Keyence VHX 700

The sputter profile after end of use had big visible differences

Fig. 1 The 3 target pieces, obviously coarse grained on the left side, medium sized and fine grained right hand side

Fig. 2 The 3 target pieces cut for examinations – higher magnified the striking difference of grain size

Scanning Electron Microscopy – Comparison

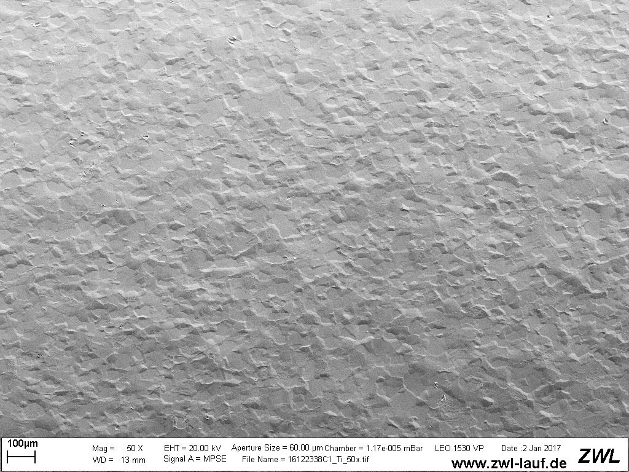

Fig. 3 Sputtered surface fine graines

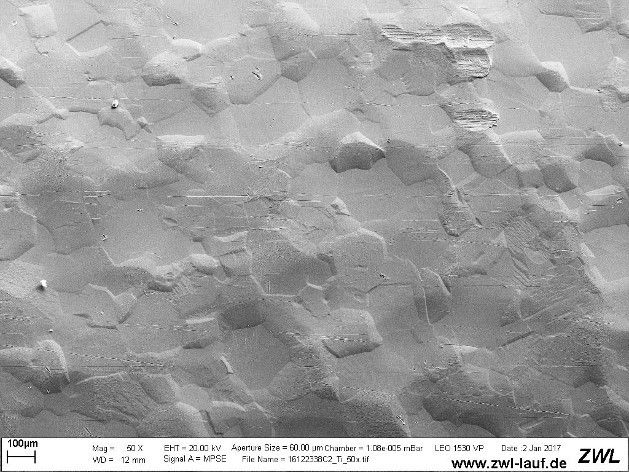

Fig 4 Sputtered surface medium grain size

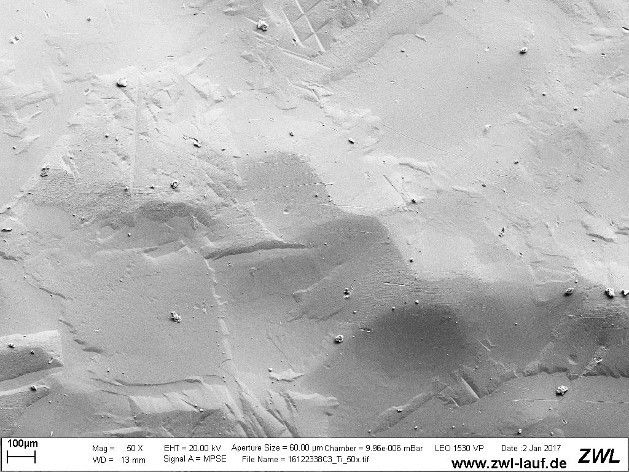

Fig. 5 Sputtered surface coarse graines

Conclusions

The fine grained sample shows a quite unusual small grain size of 33 µm. Additionally the macro-structure reveals a residue cold working texture parallel to the flat target plane. The medium size grain sample exhibits a quite uniform grain distribution of about 121 µm. Residue cold working patterns disappeared.

The coarse grain size sample shows the big grains, locally more than 1 mm in diameter

a few millimeters beneath the sputter surface. Towards the cooled back side (bottom) of the target, the grain size ranges comparable with the medium grain size sample.

These findings can be explained as follows:

The as received condition of the target material shows a very fine grain size and still cold working texture patterns.

Presumably the target material was not enough heat treated after the last milling step.

Depending on the local temperature distribution in the sputter chamber, the targets were “heat treated”, leading to a recrystallization.

Weight comparison of the eroded targets showed that the fine grain size materials usage yield was in average 6, 4 % higher than the coarse grain size.

Kommentare